- Min Order: 1 set

- Supply Quantity: 200 sets/month

- Loading Port: Qingdao Port

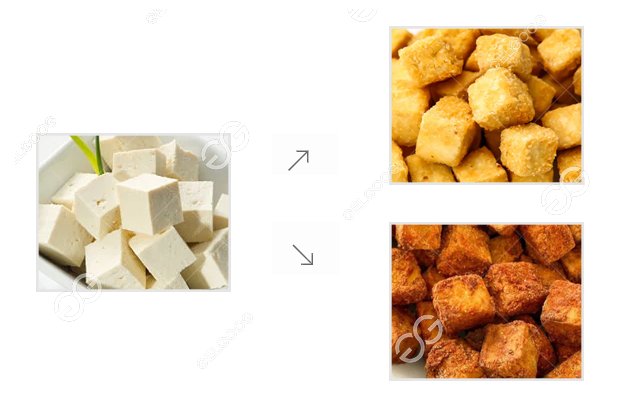

- Description: This fully automatic tofu frying line also applies to fry pork rinds, peanuts, broad beans, green peas, rice crust, high efficiency, saving oil and labor.

Fully Automatic Fish Tofu Frying Machine Line

Application of Fully Automatic Fish Tofu Fryer Machine

This fish tofu frying machine adopts oil-water mixture technology, equipped with dynamic filtration system, filter slag in the working process, guarantee the purity of frying oil. Less investment, high thermal efficiency, reduce the production cost of users. Suitable for fish, poultry, aquatic products, meat, meat pie, balls, rice crust mass production.

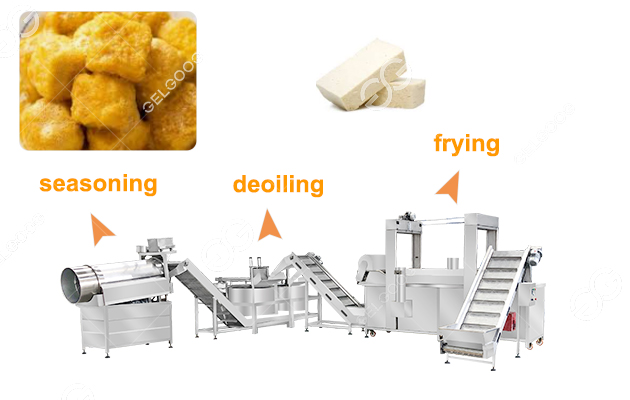

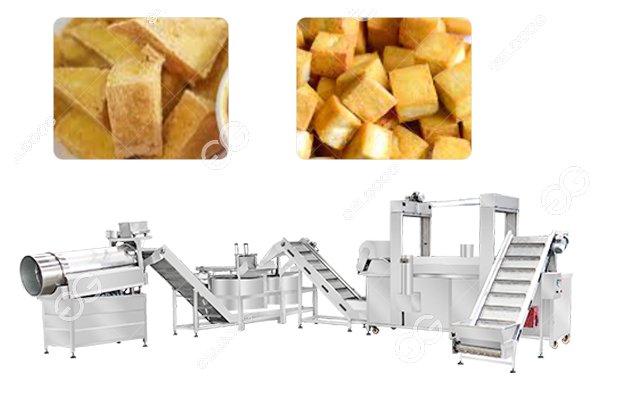

Composition Of Tofu Frying Line

This tofu frying line mainly includes frying machine, de-oiling machine, seasoning machine, hoist and so on.

Tofu frying machine: The tofu is deep-fried with an oil-water separation type frying machine. The oil temperature is controllable throughout the process, and the degree of automation is high, which is more fuel-efficient.

De-oiling machine: Tofu after frying is too much to produce a greasy feeling, and it needs to be de-oiled. Reduce greasy feeling.

Seasoning machine: modulate the fried tofu into different flavors.

Features Of Tofu Frying Line

Fried Fish Tofu Frying Production Line Equipment Introduction

1. Frying system: Adopting double stainless steel spiral mesh belt. An integral control frequency conversion motor, mesh belt speed adjustable frequency converter, the distance between upper and lower mesh belt is adjustable, can meet the processing requirements of different products. Pressing mesh belt belt can guarantee the products under edible oil, scraper way of discharging, discharge completely.

Fried Food

2. Heating system:

4. Scraping slag system: Control alone, according to the actual production need to open it. By scraping the slag board slowly drive, recycle oil in the residue. Residue after collection in residue collecting tank, may clean up at any time, ensure the quality and use of cooking oil cycle.

5. Control system: The control cabinet is made of stainless steel material, waterproof, good ventilation cooling effect, button control panel, can quickly realize the control and parameter adjustment of the equipment.

Our Service

This fish tofu frying machine adopts oil-water mixture technology, equipped with dynamic filtration system, filter slag in the working process, guarantee the purity of frying oil. Less investment, high thermal efficiency, reduce the production cost of users. Suitable for fish, poultry, aquatic products, meat, meat pie, balls, rice crust mass production.

Composition Of Tofu Frying Line

This tofu frying line mainly includes frying machine, de-oiling machine, seasoning machine, hoist and so on.

Tofu frying machine: The tofu is deep-fried with an oil-water separation type frying machine. The oil temperature is controllable throughout the process, and the degree of automation is high, which is more fuel-efficient.

De-oiling machine: Tofu after frying is too much to produce a greasy feeling, and it needs to be de-oiled. Reduce greasy feeling.

Seasoning machine: modulate the fried tofu into different flavors.

Features Of Tofu Frying Line

- High performance

- long lasting

- Automatic simple operation

- Low maintenance

- Meets food safety standards

- Applications: manufacturing plants, commercial catering, restaurants, food processing plants

Fried Fish Tofu Frying Production Line Equipment Introduction

1. Frying system: Adopting double stainless steel spiral mesh belt. An integral control frequency conversion motor, mesh belt speed adjustable frequency converter, the distance between upper and lower mesh belt is adjustable, can meet the processing requirements of different products. Pressing mesh belt belt can guarantee the products under edible oil, scraper way of discharging, discharge completely.

Fried Food

2. Heating system:

- The direct internal heating, electric heating tube tubular heating tube.

- The electric heat pipe is located in the middle of transporting mesh belt, timely and efficiently heat up, to meet the normal production.

- Can up and down together with the mesh belt bracket, convenient for maintenance.

- The whole frying area is divided into two period of temperature control.

4. Scraping slag system: Control alone, according to the actual production need to open it. By scraping the slag board slowly drive, recycle oil in the residue. Residue after collection in residue collecting tank, may clean up at any time, ensure the quality and use of cooking oil cycle.

5. Control system: The control cabinet is made of stainless steel material, waterproof, good ventilation cooling effect, button control panel, can quickly realize the control and parameter adjustment of the equipment.

Our Service

- One year warranty, video technical support, 24-hour online technical consulting service.

- Installation and transportation: All parts of the machine are first packed in a solid wooden box to ensure the safety of customers' products.

- Installation training: provide telephone guidance for equipment installation and commissioning; or send technicians to install and commission the machine.

|

No. |

Name |

Qty (set) |

Power (kw) |

| 1 | Continuous Deep Fryer | 1 | 2.25 |

| 2 | Oil filter | 1 | 1.5 |

| 3 | Deoiling Machine | 1 | 1.5 |

| 4 | Lifting Machine | 1 | 0.55 |

| 5 | Cooling Machine | 1 | 8.6 |

| 6 | Rotary Flavoring Machine | 1 | 2.25 |