- Min Order: 1set

- Supply Quantity: 100/month

- Loading Port: qingdao

- Description: The equipment we provide for potato chip processing plants is an efficient production method, which is favored by customers in different countries.

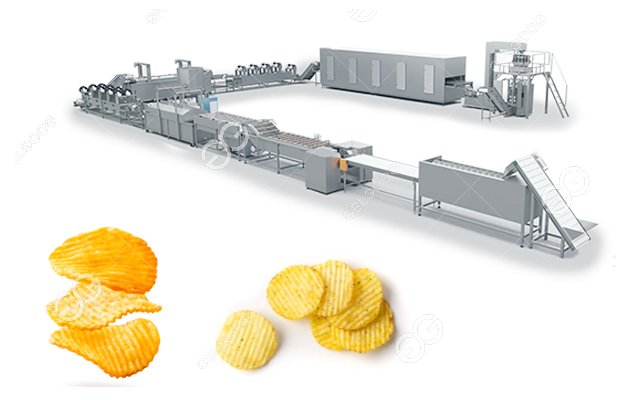

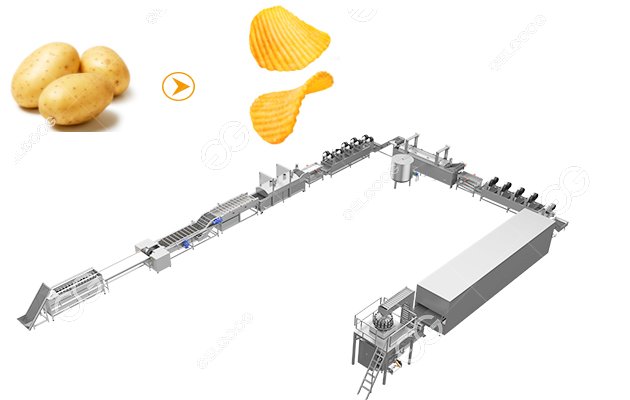

High Quality Wave Shape Potato Chips Processing Plant Customizable

This wave shape potato chips processing line is mainly used for the processing of puffed food using potatoes as raw materials, and can meet different shapes of finished products, such as wavy potato chips, potato chips, French fries and so on. It is a fully automated production line that can be customized according to the customer's plant requirements.

Wave Shape Potato Chips Manufacturing Process Flow Chart

Advantages Of The Potato Chips Processing Plant

- Fully automated production method saves a lot of labor costs.

- All machines are made of high-quality 304 stainless steel, which has a long service life and is easy to clean.

- Each individual machine can be customized according to customer needs.

- Stable operation, reasonable design, can be used flexibly.

- Easy to move, most of the equipment is equipped with pulleys to move at the bottom.

Potato Chips Processing Plant Work Video

Wave Shape Potato Chips Manufacturing Machines

The complete wave potato chip production line mainly includes the following machines:- Potato washing and peeling machine: Thoroughly wash potatoes and achieve the effect of peeling.

- Sorting conveyor: pick out potatoes with oil defects.

- Wave shape potato chip cutting machine: Cut potatoes into wave patterns, and the cutting thickness of wave potato chips can be adjusted.

- Wave shape potato chip sorter: remove unqualified wave potato chips

- Bubble cleaning machine: The principle of high-pressure water flow and bubble impact is used to wash away the excess starch on the surface of the wave potato chips.

- Wave shape potato chip blanching machine: Inhibit the activity of enzymes and play a role in color protection.

- Vibration dehydrator: remove the moisture on the surface of the potato chips and transport them to the next machine evenly.

- Air-air cooler: Use the principle of air blowing to completely remove the moisture on the surface of the potato chips to prevent the phenomenon of diving during frying.

- Elevator: conveying potato chips to frying machine.

- Potato chips continuous fryer machine: Continuously fry wave shape potato chips, the fried product has a longer shelf life.

- Vibration oil removal machine: remove excess oil on the surface of fried potato chips.

- Seasoning machine: seasoning according to different flavors.

- Automatic packaging machine: It is convenient to pack wave shape potato chips for sale.

Installation Service And After-sales Service

- 12 months free warranty.

- Professional after-sales service personnel provide services to customers.

- Before the machines leaves the factory, we will arrange professional engineers to complete the commissioning according to the customer's requirements.

- Provide installation instructions, video installation, operation instructions and maintenance instructions.

- We can provide video-guided installation technology according to the customer's requirements to ensure that the customer is put into production normally.

| No.1 | Euipment | Function | Power | Dimension |

| 1 | Slicing Machine | Slicing the peeled plantain | 1.5kw | 900*700*1100mm |

| 2 | Elevator | Lifting the plantain chips | 0.75kw | 1800*1000*1500mm |

| 3 | Frying Machine | Refry the plantain chips | 1.5kw | 5000*1400*2200mm |

| 4 | Vibration De-Oiling Machine | Remove the extra oil of the plantain chips | 0.5kw | 1800*1230*1020mm |

| 5 | Seasoning Machine | Seasoning plantain chips | 1.5kw | 1800x900x1600mm |