- Min Order: 1set

- Supply Quantity: 100/month

- Loading Port: qingdao

- Description: This continuous frying machine chips is suitable for the production of a variety of snacks, including Nigerian street food, Korean food, fast food, etc.

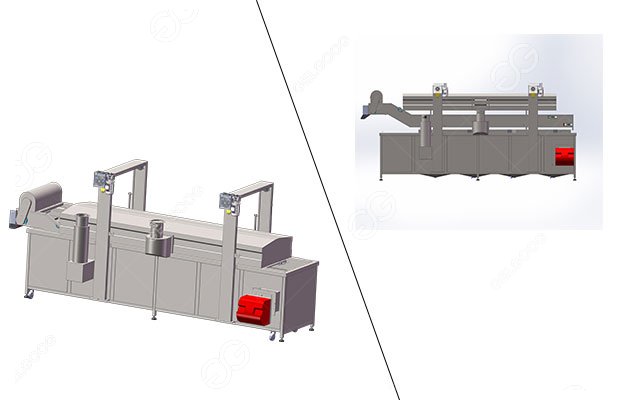

Continuous Yam Chips Frying Machine

As a professional snack food frying machine supplier, we are committed to providing customers with the highest quality automatic frying system. The working principle of this continuous frying machine chips: the product is fed from one end, and the other end is fried through a conveying system, which is widely used in the food processing industry. In addition, the Yam chips frying machine we provide can provide different designs and specifications according to customer needs.

Features Of Continuous Frying Machine chips

Quality Of The Oil Can Be Guaranteed

Floating products: Gathiya, potato chips, corn chips, Yam chips, Papdi, tortilla chips, etc.

Non-floating products: beans, meat, broad beans, coated peanuts, nuts, green beans, etc.

Our automatic continuous frying machine chips can be designed to meet different frying requirements, some of which are as follows:

Features Of Continuous Frying Machine chips

- This kind of food machine is a double mesh belt type made of stainless steel.

- Equipped with an automatic temperature control device, heating energy sources are electricity, gas, and coal.

- Detachable conveyor design, easy to clean

- Automatic temperature control, so that the machine is always in a good heating system, avoiding energy waste.

- The Yam chips frying machine can work continuously to improve work efficiency and reduce costs.

Quality Of The Oil Can Be Guaranteed

- Fine filtration can remove residues and ensure that the oil is clean enough.

- Low fuel consumption, ensuring low cost and high shelf life.

- Edible oil can be used multiple times to reduce waste.

- Quick oil cooling to reduce the degree of oxidation.

Floating products: Gathiya, potato chips, corn chips, Yam chips, Papdi, tortilla chips, etc.

Non-floating products: beans, meat, broad beans, coated peanuts, nuts, green beans, etc.

Our automatic continuous frying machine chips can be designed to meet different frying requirements, some of which are as follows:

- Potato Chips/Bars

- Banana chips and plantain chips

- Snacks and puffed food

- Onion slices/rings/noodles

- Salty (Namkeen /Chanachur)

- Beans and nuts

- Chicken/fish

- French fries

- When raising the continuous frying machine chips, insert the bumper at any time to prevent the cover from falling and hurting people.

- It is forbidden to touch high-temperature parts directly with hands.

- Avoid slipping caused by spilled frying oil.

- The electric control cabinet, motor, and operation buttons should be protected from water ingress.

- When raising the fryer, make sure that there are no other sundries on the cover of the fryer.

- The valve and the power switch must be closed before cleaning, and the power switch control cabinet must be covered with plastic to prevent the water inlet electrical appliances from being burned out by a short circuit.

- Pay attention to high temperatures. During the frying time, the operators on-site can't stay on duty.

- Clean regularly to prevent fires caused by responsible accumulation.

- After frying, close the frying oil inlet and outlet valves and release the remaining oil in the frying tank for filtering or oil washing.

| Model |

Belt width (mm) |

oil pump power (kw) |

lifting power (kw) |

heating power |

Dimension (mm) |

| LZG3500A | 800 | 1.5 | 0.55 | 20Wkcal | 3700*1900*2400 |

| LZG5000A | 800 | 1.5 | 0.55*2 | 30Wkcal | 5200*1900*2400 |

| LZG6500A | 800 | 1.5 | 0.75*2 | 20Wkcal*2 | 6700*1900*2400 |

| LZG8000A | 800 | 2.2 | 0.75*2 | 30Wkcal*2 | 8200*1900*2400 |

| LZE3500A | 800 | 1.5 | 0.55 | 90KW | 3700*1600*2200 |

| LZE5000A | 800 | 1.5 | 0.55*2 | 120kw | 5200*1600*2200 |

| LZE6500A | 800 | 1.5 | 0.75*2 | 190kw | 6700*1600*2200 |

| LZE8000A | 800 | 2.2 | 0.75*2 | 255kw | 8200*1600*2200 |