- Min Order:

- Supply Quantity:

- Loading Port:

- Description: As reliable suppliers for fried chicken machine, GELGOOG provides food quality automatic frying machine and excellent service.

Fried Chicken Nuggets Frying Machine Production Line

Automatic fried chicken nuggets production line the whole machine is made of 304 stainless steel, machine length, width, and production output can be customized according to the user's needs. There are single mesh belt and double mesh belt used for different fried food, and digital display temperature and can be controlled, the user can set the oil temperature according to the different fried products requirement. Automatic filtration system is divided into two types: oil-water mixing process, automatic oil scraping and frying technology.

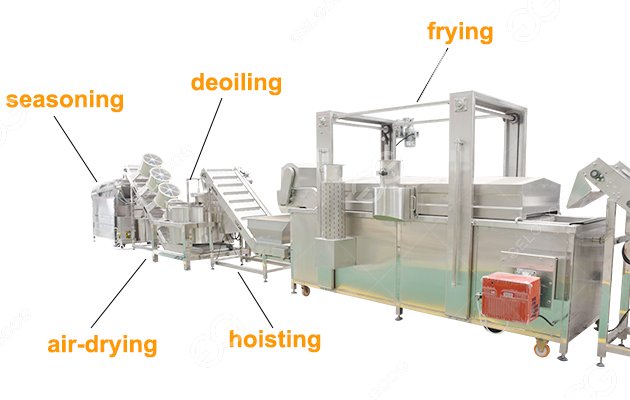

Production Process Of Chicken Nuggets Frying Line

- Elevator: Lift the chicken nuggets to be fried to the fryer machine.

- Chicken nuggets frying machine: Deep-fry chicken nuggets.

- De-oiling machine: remove excessive oil on the surface after frying.

- Air dryer: using high pressure and strong cold air blowing.

- Seasoning machine: season the chicken nuggets.

- All stainless steel fryer, and frying temperature can be controlled automatically. Different temperatures can be set according to fried food. The frying time can be adjusted according to frying requirements.

- Unique fried food conveying system, slag discharging system, oil circulation system, smoke exhaust system, electronic control system and other components. Mesh belt conveyor for frequency conversion or stepless speed regulation;

- High degree automation, automatic or manual lifting system, unique product delivering system, slag discharge system, heating system, etc.

- The use of mesh belt transmission products or variable speed or stepless speed regulation. Widely used in meat, fried chicken wings, meat products, rice, Pakistan, aquatic products, vegetables, pasta and other fried food processing.

- The design of the gas frying assembly line is compact and reasonable, the operation is simple, the heating is even, the operation is stable, the daily cleaning is convenient and the maintenance is simple.

- Continuous chicken nugget frying line not only meets the requirements of food processing technology during use, but also improves the product yield and improves the product quality, reduces production costs, reduces labor intensity, and enhances the market competitiveness of fried chicken nuggets.

Application of industrial Chicken Nuggets Production Line

Chicken nuggets frying line has wide application, especially for meat products (chicken products, duck products, chicken conditioning products, deep-frozen frozen foods, etc.), seafood (Dongting Lake fish, hairy fish, Taihu freshwater fish, squid, squid Fish, yellow croaker, octopus, etc.), pasta products (coconut rice, chic chin, glutinous rice cakes, cat ears, dough, puff puff, etc.), vegetables (eggplants, potatoes, french fries, potato chips, honeysuckle leaves, mint leaves, kidney beans, etc.). The frying equipment can realize the frying temperature and the frying time can be arbitrarily set within the specified range. It can meet the diversified demands of different products and is the first choice for food processing enterprises and catering supporting enterprises.

| No. | Name |

Quantity (set) |

Power (kw) |

| 1 | Gas Continuous Deep Fryer | 1 | 2.25 |

| 2 | Oil filter | 1 | 1.5 |

| 3 | Bottom Discharging Deoiling Machine | 1 | 1.5 |

| 4 | Conveying and Lifting Machine | 1 | 0.55 |

| 5 | Cooling Machine | 1 | 8.6 |

| 6 | Rotary Type Seasoning Machine | 1 | 2.25 |